This machine is the first step for manufacturing of plastic stationery products. It converts PP granules to PP Sheet as per pre-defined sizes and thickness.

Used to cut paper and plastic sheets to required sizes.

Useful for Sheet cutting in clear and accurate shape. Large bed to cut sheets of both small and big sheet sizes.

The company owns more than 30 semi-automatic and fully automatic machines for combining PP Sheet and accessories to make different types of Files and Folders. This includes:

Clip Fitting Machines

Button Fixing Machines

Heat Welding Machines

Company owns multiple lines of fully automatic Clear Folder/ Sheet Protector making machines for high quality and economical production of folders in varied sizes.

Industrial grade sewing machines are used to manufacture products with high quality stitching.

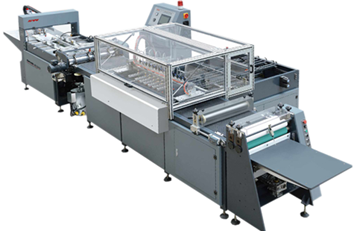

The company is the India's first and only owner of a fully automatic case making machine (In Stationery Industry) capable of producing at least 10000 cases for Lever Arch File per day. The machine is very useful for getting high quality and stable production of both Paperboard and PVC covered Lever Arch File board as per the defined specifications. .

The company owns more than 25000 sq ft of Warehouse space with well organised racking and labelling system ensuring easy identification and traceability of goods and materials. .

We have a very well equipped in-house testing lab to make sure the correct raw materials are used to manufacture product as per correct size, thickness, color and strength.

Instruments used include:

Color matching box

Micrometers

Strength Tester

GSM Calculator

Weighing Scales

Verniers

This is the second step for production of all types of products. Useful for High-speed cutting at speeds approx 5000 sheets per hour and touchless mechanism for scratch less high quality cutting.